Our Polymer Testing Services

Elemental & Chemical Analysis

The base material, chemical structure, chemical composition and physicochemical properties can

significantly impact the polymer's function. For example, polymeric functional membrane materials

require the polymer to have a microporous structure or a diffusion function to meet the selective

permeation requirement of the separated material in the membrane. The reactive functional polymer

needs

to have a certain swelling property or a range of porosity and pore size distribution to satisfy the

diffusion of the reaction substance therein. Other functional polymer materials have certain

requirements for polymer chemistry properties, mechanical properties and thermal stability. Our

polymer

and material science division provide the following elemental and chemical testing services,

- Elemental analysis of polymers

- Identification of unknown polymeric materials

- Analysis of toxic impurities

- Chemical resistance testing

- Molecular weight distribution

- Chemical bonds, molecular structure & compositional analysis

- Total molecular weight analysis

- End group analysis

- Polymer blends, co-monomer concentrations and ratios, and co-polymer backbone chemistry

- Additive & resin identification

- Chemical analysis, including base polymer characterization

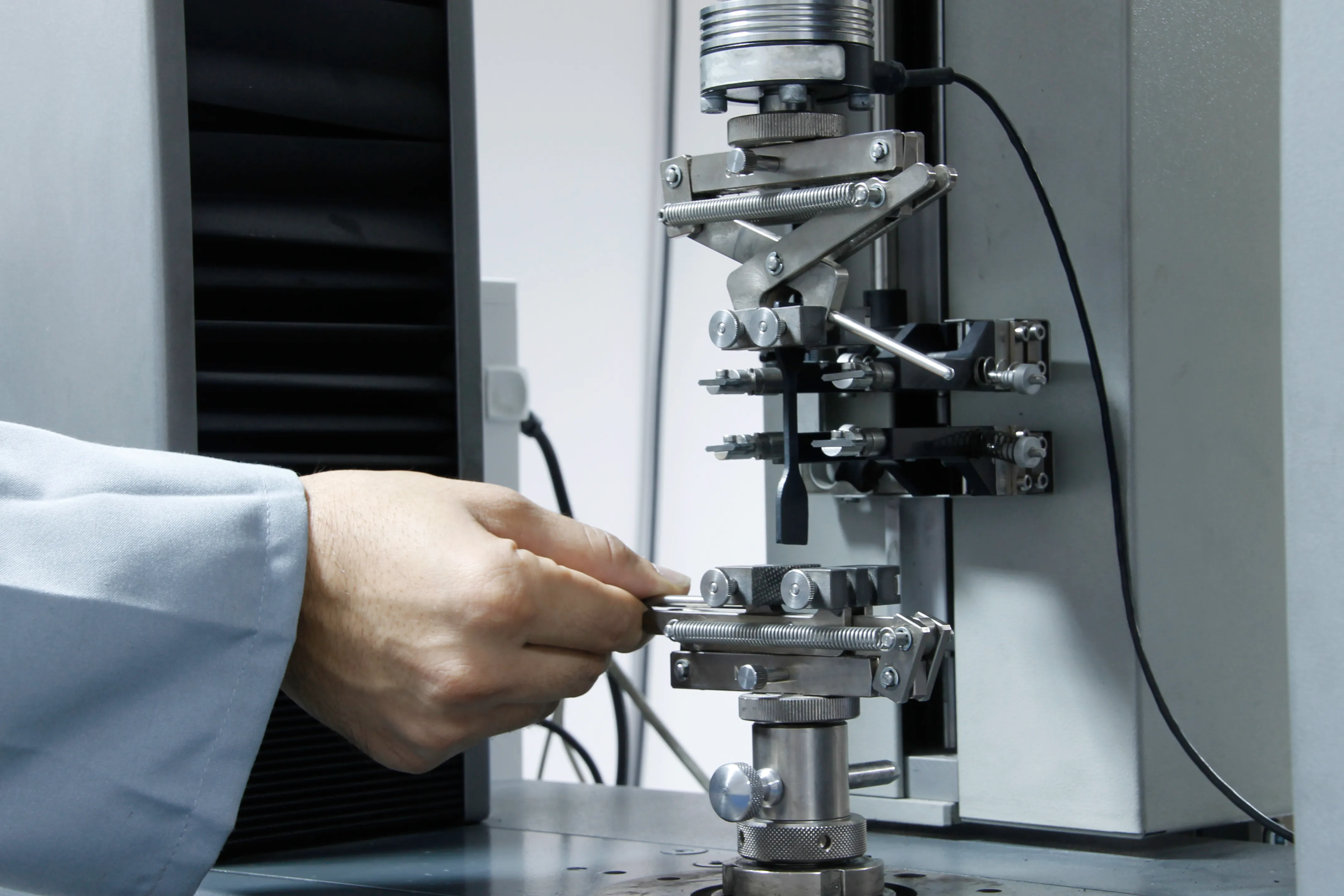

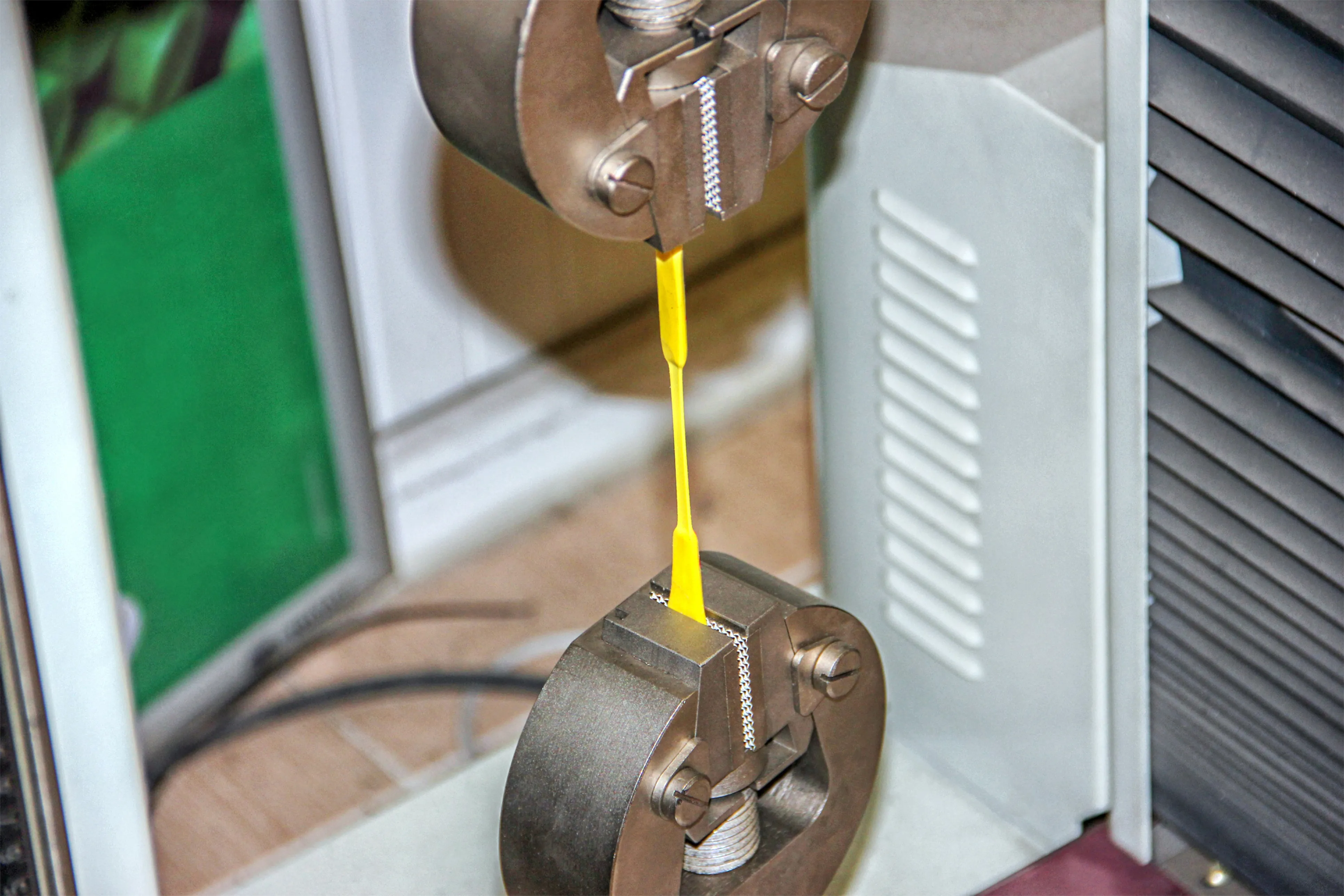

Polymer Physical and mechanical Testing

The mechanical characteristics of polymers serve as the foundation for a number of exceptional

physical

attributes and are the primary determinants of the sensible use of polymer materials. With polymer's

prevalent applications, it is urgent to understand and master the general laws and characteristics

of

the mechanical properties of polymers and their relationships with the structure, so as to correctly

control the processing conditions and properly obtain the required polymer materials. For example,

the

polymer must withstand the tensile force when used as a fiber; it must withstand the tapping when

used

as a plastic product; and it must possess elasticity and wear resistance when used as a rubber. Our

physical and mechanical testing involved,

Physical Properties Testing

- Density

- Specific gravity

- Water absorption

- Water vapor permeability

- Contact angle measurements

- Rheological tests

- Intrinsic viscosity

- Melt processing characterization

- Melting point

- Refractive index

- Crystallinity

Mechanical Properties Testing

- Tensile strength

- Flexural strength

- Compressive strength

- Impact resistance

- Crush strength

- Shear resistance

- Interlaminate strength

- Hardness

Other Characterizations

- Void content

- Volatile organic content (VOC)

- Heavy metals

- Ash

- Flash point

- Color

- Pigment & filler dispersion

Thermal Analysis

With the development of the polymer synthesis industry and the expansion of polymer application

fields,

more requirements have been proposed for the types and properties of polymer materials. In order to

develop new types of high polymers and control their quality and performance, it is essential to

determine the melting temperature (Tm), glass transition temperature (Tg), composition of the

mixture

and copolymer, thermal history, and crystallinity of the polymer. To obtain these parameter values,

thermal analysis is the main analytical tool. A group of methods known as thermal analysis are used

to

measure the characteristics of samples under program-controlled temperature fluctuations or over

time.

Our thermal analyses cover,

- Glass transition temperature (Tg)

- Melting (Tm) & Boiling point

- Thermal and oxidation stability

- Viscoelasticity and crystallization

- Dimensional stability

- Heat deflection temperature

- Dielectric properties

Polymer Structure & Morphology Analysis

The study of polymer morphology represents an interdisciplinary approach from the Nano level (e.g.,

polymer structure, conformation, and crystallinity) to the macrolevel (e.g., surface morphology of

final

products, fibers, foils, blends, and composites). It means that the structural analysis of polymer

can

be divided into two types: microstructure morphology and macrostructure morphology. The

microstructure

of a polymer is related to the physical arrangement of monomer residues along the backbone of the

chain

and it determines its macroscopic physical and mechanical properties, such as the crystallinity, the

glass transition temperature, or microphase separation phenomenon. On the other hand, the

macrostructure

morphology is related to the interactions between the polymer chains. Both features are very

essential

and useful, playing a major role in determining the physical and chemical properties of a polymer.

Our,

polymer structure morphology analysis services include,

- Shape & size

- Roughness & topography

- Cross-section morphology

- Defect analysis

- Distribution of micropores & defects

- Crystal size

- Uniformity of the Nano/micro scale phase dispersion

- Crystalline state

- Electron Microscopy (EM)

- Differential Thermal Analysis (DTA)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Thermomechanical Analysis (TMA)

- Dynamic Mechanical Analysis (DMA)

- Dielectric Thermal Analysis (DETA)

- Intrinsic Viscometer

- Universal Testing Machine (UTM)